Round natural rubber bearing

Natural rubber bearing, short for NRB, is a kind of seismic isolation bearing with alternately piled up multi-layer natural rubbers and multi-layer steel plates. This bearing offers a higher vertical load capacity and a greater horizontal flexibility. It has been widely used in the seismic isolation design of residential buildings, office buildings, hospitals and other buildings, and has achieved great economic and social benefits.

As the NRB has a low energy dissipation capacity, therefore, it often forms a seismic isolation system together with dampers.

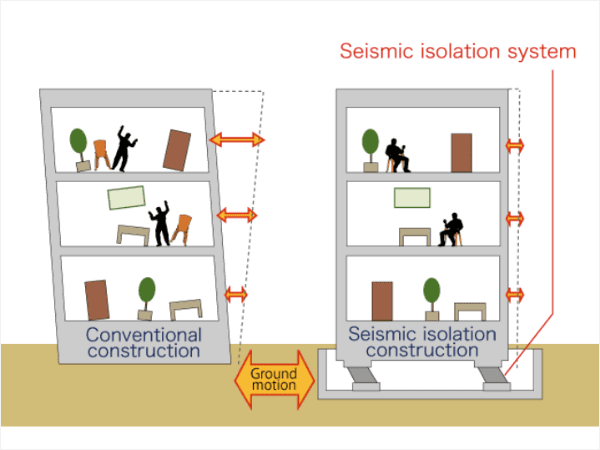

By installing natural rubber bearings between the superstructure and the foundation, a seismic isolation layer is formed, achieving a soft connection with the ground to turn the violent shaking of the building into a slow horizontal movement, thereby reducing the input of seismic energy.

At the same time, the NRB separates the superstructure from the lower foundation. When the earthquake occurs, the vibration energy of the lower foundation will be transferred to the natural rubber bearing first. By taking advantage of the characteristics of the combination of rigidity and flexibility of the NRB, the transmission of seismic energy to the upper structure can be effectively avoided or reduced, thereby ensuring the safety of the superstructure and appurtenances inside.

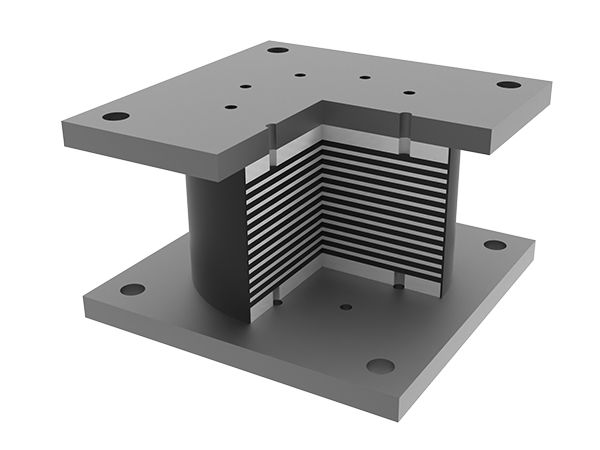

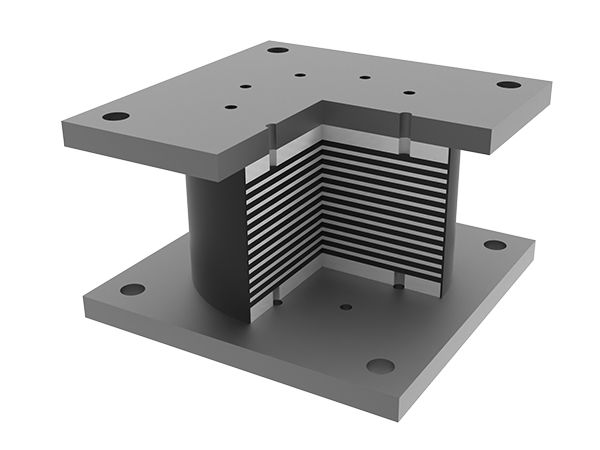

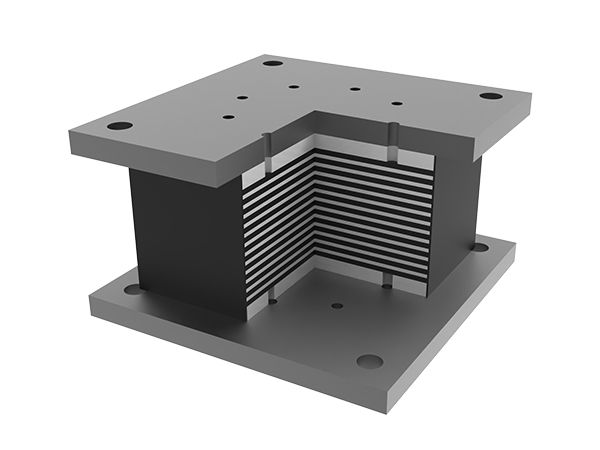

Natural rubber bearing consists of a top and a bottom connecting steel plates, a top and a bottom sealing plates, internal natural rubber layers, internal steel plates and a rubber cover.

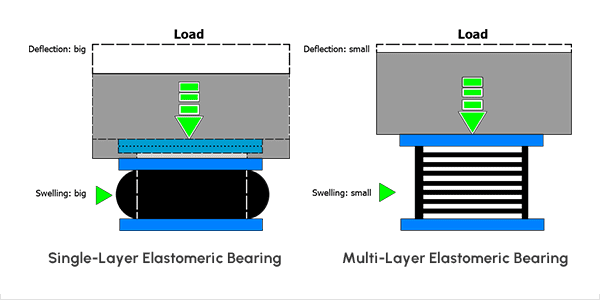

When the NRB is subject to a vertical pressure, rubber sheets and steel plates are radial deformed. However, the deformation of steel plates is much smaller than that of rubber sheets, therefore, rubber sheets are constrained by steel plates, thus limiting the vertical compression deformation of rubber sheets to ensure that the bearing has a higher vertical bearing capacity and provides a stable support to the building.

When the NRB is subject to a horizontal pressure, laminated steel plates cannot restrain the shear deformation of rubber sheets. At that time, the horizontal deformation of the bearing is approximately the sum of the horizontal deformation of all rubber sheets. As a result, the bearing has a large horizontal deformation capacity.

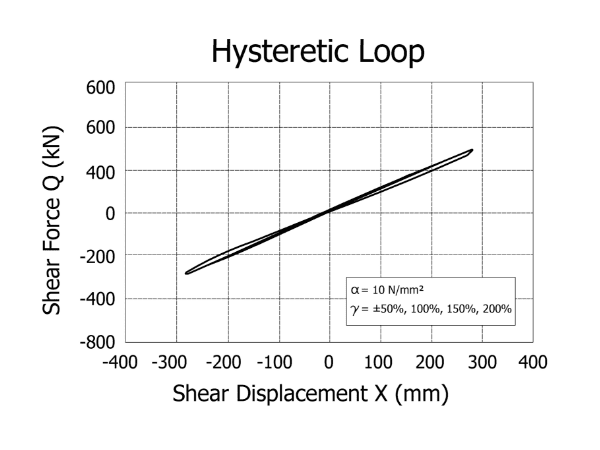

The great linearity of the hysteresis curve reveals the excellent horizontal flexibility and stable resorting force the natural rubber bearing can offer.

Rubber material preparation

Natural rubber and other auxiliary materials are processed into rubber compound by adopting internal mixing technology.

Metal part surface treatment

Sandblast the surface of the steel plate inside the natural rubber bearing. Spray rubber-to-metal adhesive on the bonding interface to ensure the integrity of the NRB.

Vulcanization

Vulcanization is required to integrate the rubber compound and treated internal steel plates into a whole unit. Generally, a large flat vulcanizer with special molds is required for vulcanization. The whole process takes about 8 to 48 hours. Specifically, it depends on the size of the NRB. Continuous monitoring is required during vulcanization to ensure that the rubber cures uniformly throughout the process.

Assembly

The pre-embedded steel plate, pre-buried sleeve, anchor bolts and the support body are assembled into a whole to finish the manufacturing of a full set of natural rubber bearing.

Natural rubber bearings are divided into round and rectangular natural rubber bearings by shape.

Round natural rubber bearing

Rectangular natural rubber bearing

| Item | NRB (G4) | NRB (G4) | NRB (G4) | NRB (G4) | NRB (G4) | NRB (G4) | NRB (G4) | NRB (G4) | NRB (G4) | NRB (G4) |

|---|---|---|---|---|---|---|---|---|---|---|

| Φ300 | Φ400 | Φ500 | Φ600 | Φ700 | Φ800 | Φ900 | Φ1000 | Φ1100 | Φ1200 | |

| Shear modulus of elasticity N/mm2 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 |

| 1st shape factor | 23.3 | 24.3 | 24.0 | 28.5 | 33.3 | 38.0 | 35.6 | 39.6 | 41.9 | 45.7 |

| 2nd shape factor | 5.17 | 5.84 | 5.10 | 5.45 | 6.36 | 5.00 | 5.56 | 6.17 | 6.65 | 7.21 |

| Effective size cm2 | 700 | 1250 | 1879 | 2820 | 3839 | 5014 | 6346 | 7834 | 9326 | 11116 |

| Datum level pressure N/mm2 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 |

| Ultimate deformation (at datum level pressure) % | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Horizontal equivalent stiffness kN/m | 470 | 710 | 710 | 990 | 1350 | 1210 | 1510 | 1870 | 2229 | 2641 |

| Vertical compression stiffness kN/mm | 844 | 1384 | 1420 | 2282 | 3632 | 3664 | 4339 | 5839 | 7347 | 9095 |

| Notes: Other specifications are available upon request. |

||||||||||

| Item | NRB (G6) | NRB (G6) | NRB (G6) | NRB (G6) | NR B(G6) | NRB (G6) | NRB (G6) | NRB (G6) | NRB (G6) | NRB (G6) |

|---|---|---|---|---|---|---|---|---|---|---|

| Φ300 | Φ400 | Φ500 | Φ600 | Φ700 | Φ800 | Φ900 | Φ1000 | Φ1100 | Φ1200 | |

| Shear modulus of elasticity N/mm2 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | 0.55 | o.55 | 0.55 | 0.55 | 0.55 |

| 1st shape factor | 23.3 | 24.3 | 24.0 | 28.5 | 33.3 | 38.0 | 35.6 | 39.6 | 41.9 | 45.7 |

| 2nd shape factor | 5.17 | 5.84 | 5.10 | 5.45 | 6.36 | 5.00 | 5.56 | 6.17 | 6.65 | 7.21 |

| Effective size cm2 | 700 | 1250 | 1879 | 2820 | 3839 | 5014 | 6346 | 7834 | 9326 | 11116 |

| Datum level pressure N/mm2 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 |

| Ultimate deformation (at datum level pressure) % | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Horizontal equivalent stiffness kN/m | 720 | 1090 | 1170 | 1540 | 2090 | 1880 | 2350 | 2900 | 3108 | 3705 |

| Vertical compression stiffness kN/mm | 1027 | 1628 | 1720 | 2688 | 4173 | 4124 | 4932 | 6532 | 7461 | 9095 |

| Notes: Other specifications are available upon request. |

||||||||||