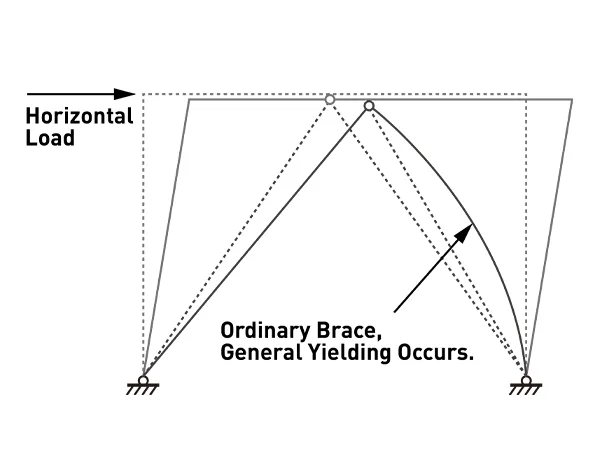

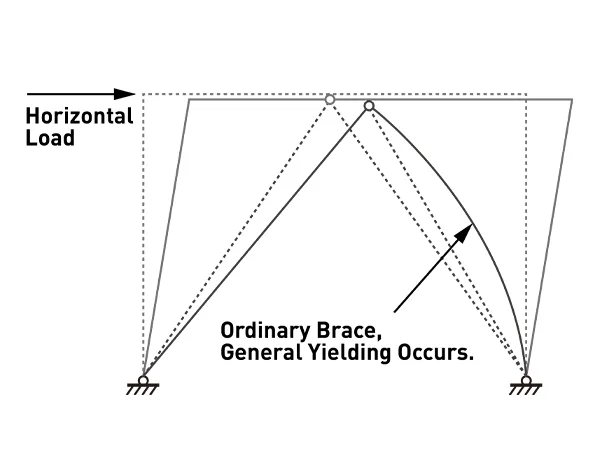

Working principle of ordinary brace

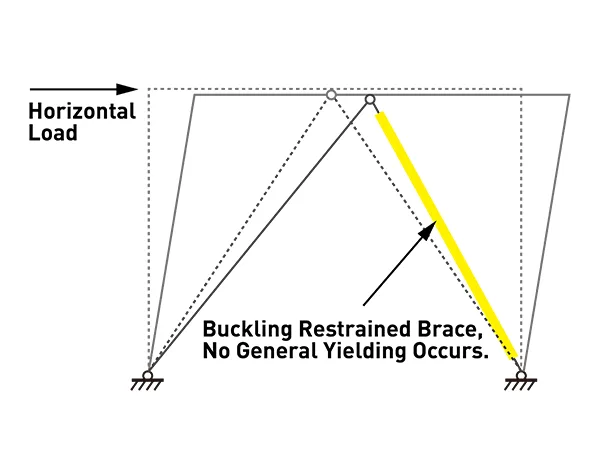

Buckling restrained brace (BRB) is an innovative structural support device designed to enhance a building's resistance to lateral loads like earthquakes. The BRB exhibits ideal elastic-plastic behavior, maintaining stable performance under repeated cyclic loads. This significantly enhances the ductility and seismic capacity of structures. Compared to conventional braces, the BRB avoids compressive buckling failure, providing an economical and reliable seismic solution.

The BRB does not buckle under load, providing a stable lateral stiffness to effectively control the overall deformation of the structure. Under seismic action, the BRB will first enter the yielding state, dissipating seismic energy through the plastic deformation of the steel core while providing additional damping, significantly reducing the impact of the earthquake on the structure. This mechanism of 'yielding but not buckling' makes the BRB a key component in enhancing the seismic performance of structures.

Working principle of ordinary brace

BRB working principle

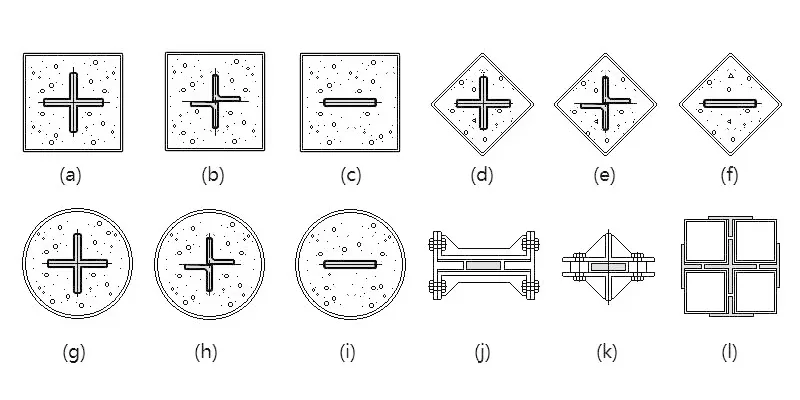

Cross-sectional views of steel cores with different layouts

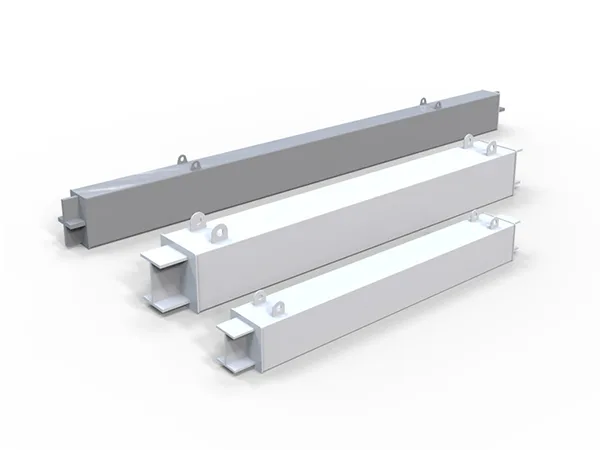

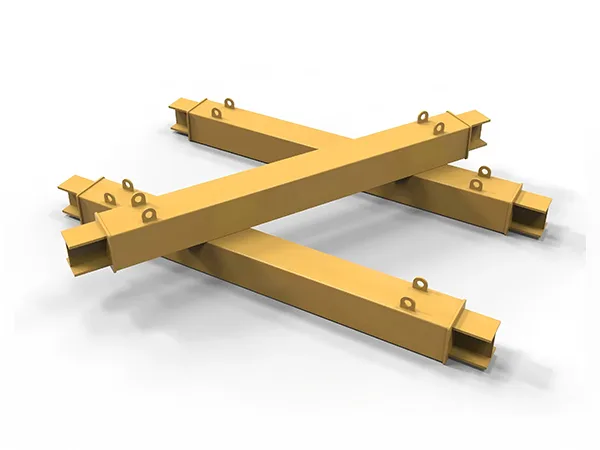

BRBs are divided into circular BRBs and square BRBs by shape. Colors are not standardized and can be customized per project requirements, with common options including yellow, white, and gray.

Blue circular buckling restrained brace

Gray and white square buckling restrained brace

Yellow square buckling restrained brace

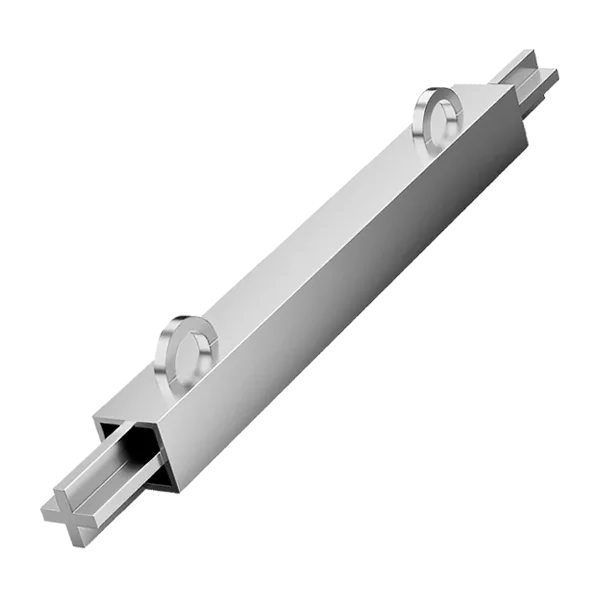

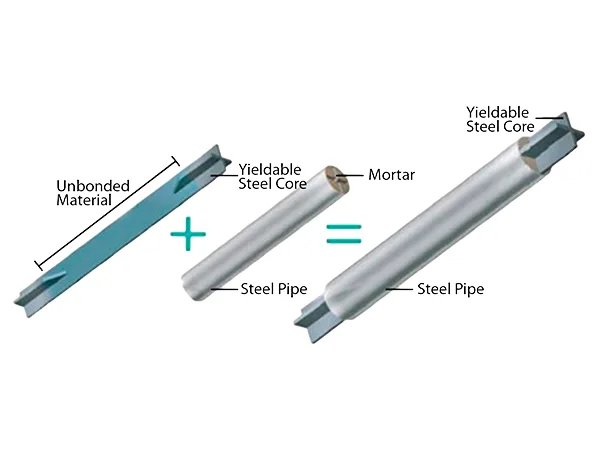

The BRB consists of four components: yieldable steel core, steel pipe, unbonded material, and mortar.

BRB structure

| Model | Yield Force (F) | Axis Length | Product Length | Reference Product Yield Displacement | Exterior Size (Width × Height) |

|---|---|---|---|---|---|

| (kN) | (mm) | (mm) | (mm) | (mm) | |

| BRB500-3500 | 500 | 5500 | 3500 | 4.8 | 150 × 150 |

| BRB500-4000 | 6000 | 4000 | 5.6 | 150 × 150 | |

| BRB500-4500 | 6500 | 4500 | 6.3 | 150 × 150 | |

| BRB500-5000 | 7000 | 5000 | 6.8 | 150 × 150 | |

| BRB500-5500 | 7500 | 5500 | 7.6 | 150 × 150 | |

| BRB500-6000 | 8000 | 6000 | 8.1 | 150 × 150 | |

| BRB750-3500 | 750 | 5500 | 3500 | 4.7 | 200 × 200 |

| BRB750-4000 | 6000 | 4000 | 5.5 | 200 × 200 | |

| BRB750-4500 | 6500 | 4500 | 6.2 | 200 × 200 | |

| BRB750-5000 | 7000 | 5000 | 6.9 | 200 × 200 | |

| BRB750-5500 | 7500 | 5500 | 7.6 | 200 × 200 | |

| BRB750-6000 | 8000 | 6000 | 8.1 | 200 × 200 | |

| BRB1000-3500 | 1000 | 5500 | 3500 | 4.7 | 200 × 200 |

| BRB1000-4000 | 6000 | 4000 | 5.5 | 200 × 200 | |

| BRB1000-4500 | 6500 | 4500 | 6.3 | 200 × 200 | |

| BRB1000-5000 | 7000 | 5000 | 6.7 | 200 × 200 | |

| BRB1000-5500 | 7500 | 5500 | 7.4 | 200 × 200 | |

| BRB1000-6000 | 8000 | 6000 | 8.2 | 200 × 200 | |

| BRB1500-3500 | 1500 | 5500 | 3500 | 4.8 | 200 × 200 |

| BRB1500-4000 | 6000 | 4000 | 5.5 | 200 × 200 | |

| BRB1500-4500 | 6500 | 4500 | 6.3 | 200 × 200 | |

| BRB1500-5000 | 7000 | 5000 | 6.7 | 200 × 200 | |

| BRB1500-5500 | 7500 | 5500 | 7.6 | 200 × 200 | |

| BRB1500-6000 | 8000 | 6000 | 8.3 | 200 × 200 | |

|

|||||

| Material Symbols | Yield Point | Tensile Strength | Yield Ratio | Elongation |

|---|---|---|---|---|

| (N/mm2) | (N/mm2) | (%) | (%) | |

| BLY100 | 100±20 | 200–300 | ≤ 60 | ≥ 50 |

| BLY160 | 160±20 | 220–320 | ≤ 80 | ≥ 45 |

| BLY225 | 225±20 | 300–400 | ≤ 80 | ≥ 40 |

| Q235B | 220±15 | 370–500 | ≤ 82 | ≥ 25 |