The safety of the structure during the earthquake is significantly improved;

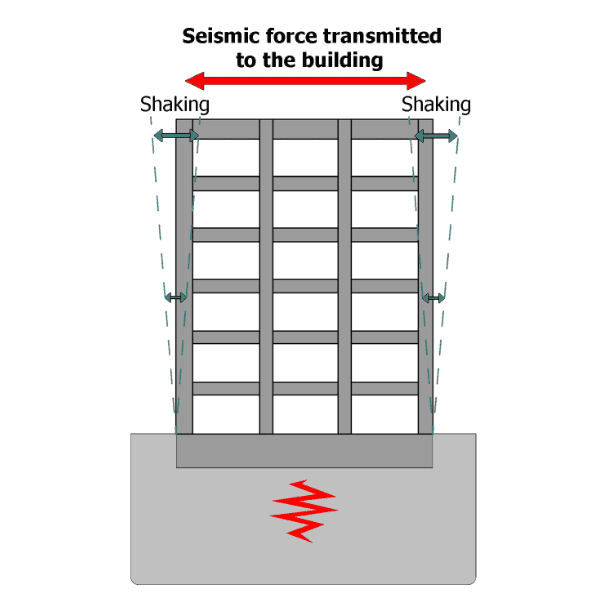

The basic principle of traditional seismic resistant structure is to improve the strength and stiffness of the structure to resistant the seismic action by adding shear walls, enlarging the cross-section size of beams and columns or increasing the reinforcement of beams and columns. That is, it stores, converts and consumes seismic energy by damaging the structure itself and the load-bearing members, which means it is a method of "hard hitting" to resist earthquakes.

The seismic capacity of the structure mainly depends on the elastoplastic deformation capacity of the structure and energy dissipation capacity of the hysteresis loop. However, the structure itself cannot adjust the seismic energy dissipation, therefore, it is commonly considered as a passive seismic resistant measure.

Seismic vibration control structure absorbs the seismic energy by attaching vibration control devices (such as dampers) to the building. The vibration control devices and the structure work together to bear the seismic action to adjust and mitigate the seismic response of the structure, thereby reducing the earthquake damage to the building.

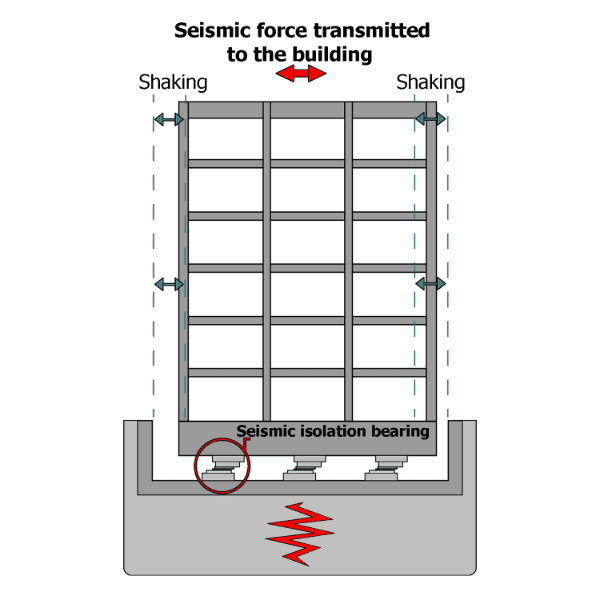

The basic principle of seismic isolation structure is to place an isolation device at the foundation or at a certain position of the building to form an isolation layer, thereby separating the superstructure from the lower foundation. As a result, the seismic energy is concentrated on the soft isolation layer and the transmission of seismic energy transferred to the superstructure is reduced by extending the natural vibration period of the whole structure system and absorbing dissipated seismic energy, thus protecting the safety of the building and appurtenances inside.

As for seismic resistant structure, when the earthquake occurs, the seismic energy is transferred to the superstructure from the foundation, leading to violent shaking. The method of resisting the earthquake through its own structure will cause huge damage to the structure and require large-scale maintenance after the earthquake.

In terms of seismic vibration control structure, similarly, when the earthquake occurs, the seismic energy is transferred to the superstructure from the foundation and the seismic energy is absorbed by vibration control devices, for example, dampers. In this way, the seismic response of the structure is reduced, however, certain damage to the structure remain occurs and requires maintenance after the earthquake.

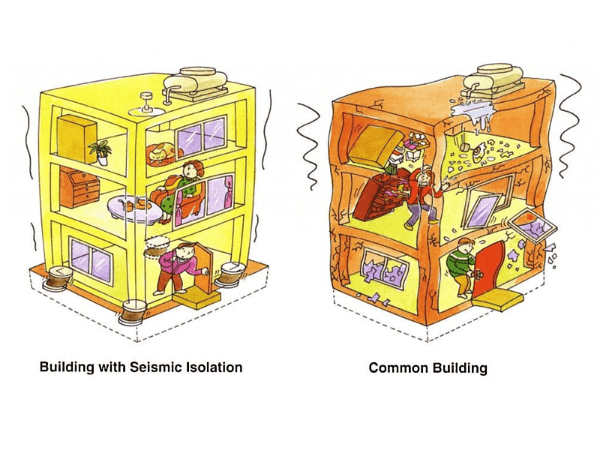

In comparison, the seismic isolation structure separates the superstructure from the foundation with seismic isolation bearings, so that the seismic energy from the lower foundation is transferred to the seismic isolation bearings first. By taking advantages of the combination of rigidity and flexibility of seismic isolation bearing, the transmission of seismic energy to the superstructure is effectively reduced or eliminated, meanwhile, the violent shaking of the structure is converted into a slow horizontal motion. As a result, it not only guarantees the integrity of the building structure and prevents non-structural components from damage, but also avoids causing damage to the objects and facilities inside the buildings as well as secondary disasters arising therefrom, requiring no maintenance after the earthquake.

The safety of the structure during the earthquake is significantly improved;

More flexible superstructure design, simple and clear seismic isolation measures;

Effectively prevent the vibration, movement and tipping of the internal objects and reduce the possibility of secondary disasters;

Prevent non-structural components from damage;

Suppress the discomfort caused by shaking and improve the sense of security and habitability;

Maintain the functions of machinery, instruments and appliances;

No maintenance is required after the earthquake, bringing in significant social and economic benefits;

Buildings built in areas where the seismic intensity scales are high, the project cost can be reduced through reasonable design.

To sum up, seismic isolation structures have become the main trend of modernization construction and are increasingly introduced into a variety of buildings, for example, hospitals, museums and residential buildings.

So far, commonly used seismic isolation bearings include natural rubber bearings, lead rubber bearings and high damping rubber bearings. We are a professional seismic isolator manufacturer and can produce seismic isolator in a variety of types and sizes to meet specific seismic resistance requirements of different buildings. If you are interested in our seismic isolators, please contact us by phone or e-mail for more information.