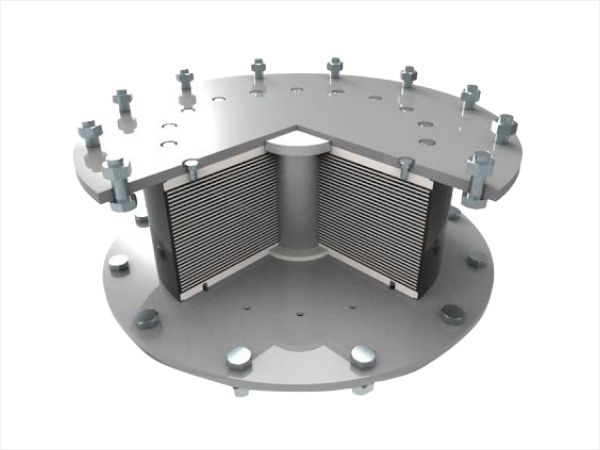

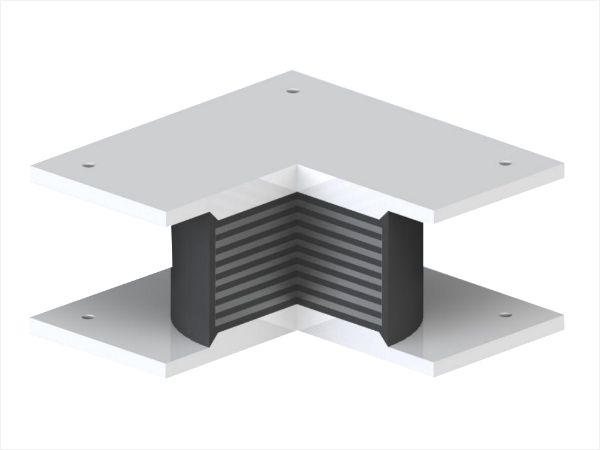

Natural rubber bearing

The horizontal stiffness of natural rubber bearing is lower than that of lead rubber bearing of the same diameter. The lower the horizontal stiffness is, the longer the natural vibration period of the structure, the lower the seismic response, the greater the seismic isolation effect. Therefore, natural rubber bearing is your preferred choice for isolation layer.